Industry

Lifestyle

Client

DeMuro Das

Retorta Cast Table • Molten Metal, Timeless Creations

Retorta Cast Table • Molten Metal, Timeless Creations

Retorta Cast Table • Molten Metal, Timeless Creations

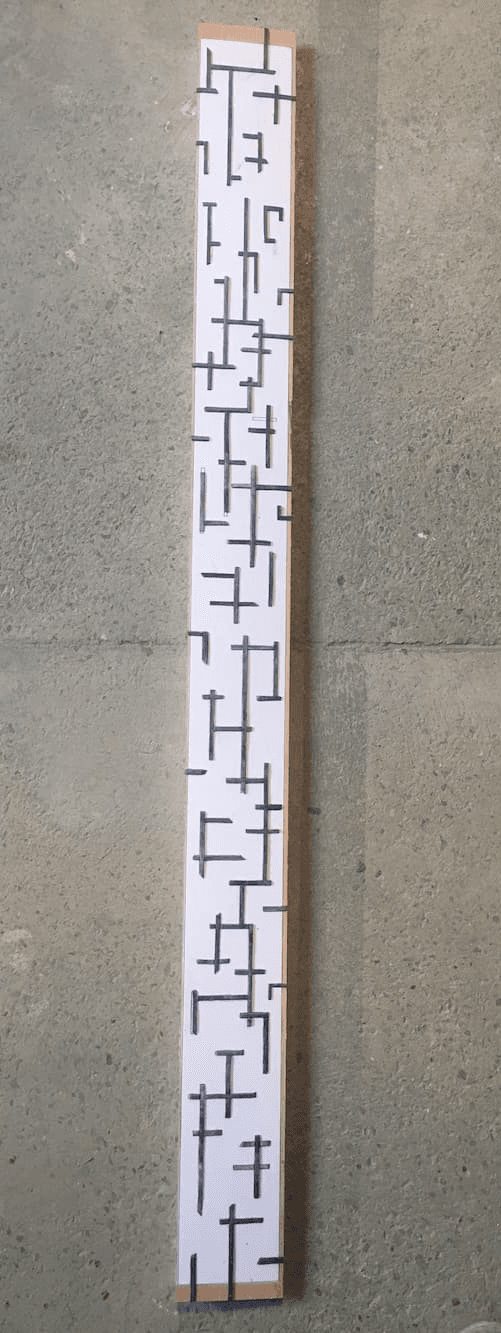

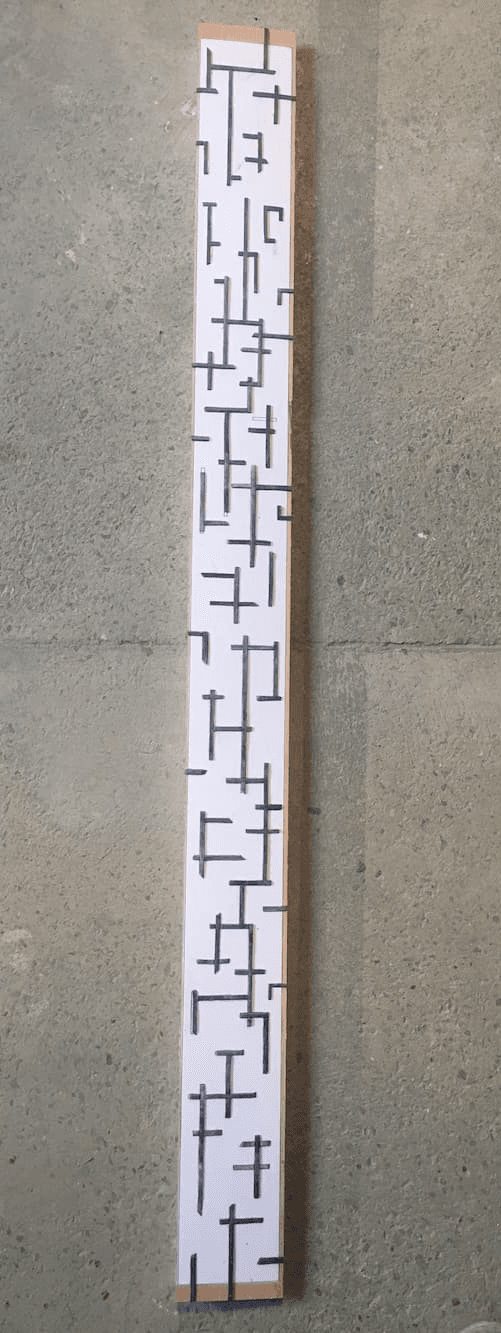

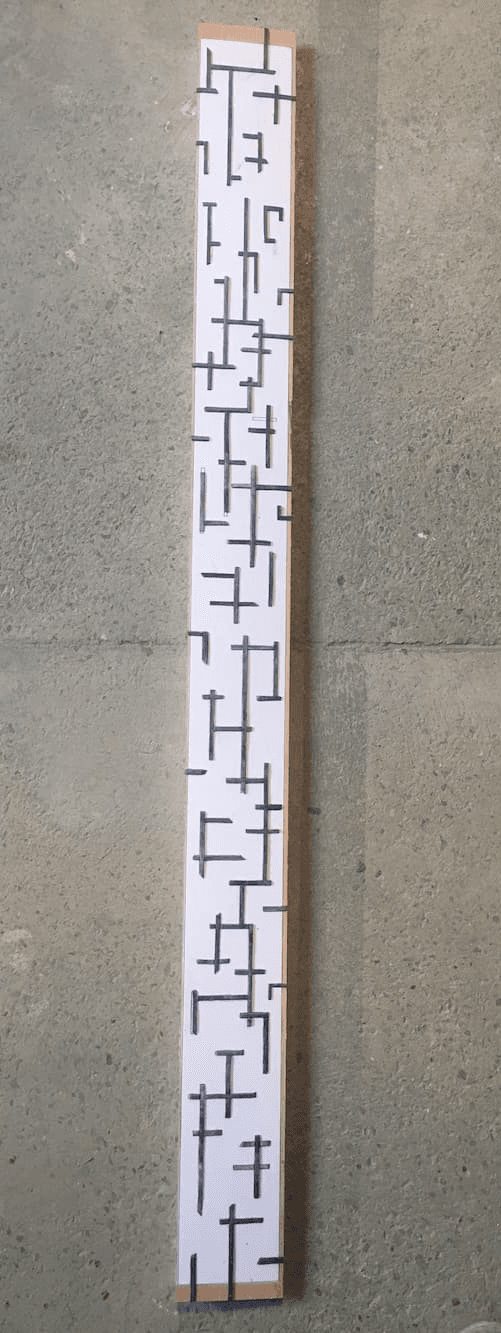

The Met mirror was a creation, drawing inspiration from the elegant curtains of the metropolitan opera house—a cherished place for the client. It served as an exploration into pattern-making through investment casting.

The Met mirror was a creation, drawing inspiration from the elegant curtains of the metropolitan opera house—a cherished place for the client. It served as an exploration into pattern-making through investment casting.

The Met mirror was a creation, drawing inspiration from the elegant curtains of the metropolitan opera house—a cherished place for the client. It served as an exploration into pattern-making through investment casting.

Design and Pattern Making: The initial phase involves designing the furniture piece and creating a pattern, often made of wood or a similar material, which serves as a template for the casting process.

Mold Making: A mold is created around the pattern using materials such as sand, clay, or silicone rubber. This mold will later be used to shape the molten brass.

Melting and Pouring: Brass, a copper-zinc alloy, is melted in a furnace at high temperatures. Once molten, it is carefully poured into the mold cavity.

Cooling and Solidification: After pouring, the brass cools and solidifies within the mold, taking on the shape of the pattern.

Shakeout and Cleaning: Once cooled, the mold is broken away from the solidified brass casting. The casting is then cleaned to remove any residual mold material or imperfections.

Finishing: The brass casting may undergo additional finishing processes such as grinding, polishing, or plating to achieve the desired surface texture and appearance.

Assembly: If the furniture piece requires multiple components, such as legs or decorative elements, these may be cast separately and then assembled together.

Design and Pattern Making: The initial phase involves designing the furniture piece and creating a pattern, often made of wood or a similar material, which serves as a template for the casting process.

Mold Making: A mold is created around the pattern using materials such as sand, clay, or silicone rubber. This mold will later be used to shape the molten brass.

Melting and Pouring: Brass, a copper-zinc alloy, is melted in a furnace at high temperatures. Once molten, it is carefully poured into the mold cavity.

Cooling and Solidification: After pouring, the brass cools and solidifies within the mold, taking on the shape of the pattern.

Shakeout and Cleaning: Once cooled, the mold is broken away from the solidified brass casting. The casting is then cleaned to remove any residual mold material or imperfections.

Finishing: The brass casting may undergo additional finishing processes such as grinding, polishing, or plating to achieve the desired surface texture and appearance.

Assembly: If the furniture piece requires multiple components, such as legs or decorative elements, these may be cast separately and then assembled together.

Design and Pattern Making: The initial phase involves designing the furniture piece and creating a pattern, often made of wood or a similar material, which serves as a template for the casting process.

Mold Making: A mold is created around the pattern using materials such as sand, clay, or silicone rubber. This mold will later be used to shape the molten brass.

Melting and Pouring: Brass, a copper-zinc alloy, is melted in a furnace at high temperatures. Once molten, it is carefully poured into the mold cavity.

Cooling and Solidification: After pouring, the brass cools and solidifies within the mold, taking on the shape of the pattern.

Shakeout and Cleaning: Once cooled, the mold is broken away from the solidified brass casting. The casting is then cleaned to remove any residual mold material or imperfections.

Finishing: The brass casting may undergo additional finishing processes such as grinding, polishing, or plating to achieve the desired surface texture and appearance.

Assembly: If the furniture piece requires multiple components, such as legs or decorative elements, these may be cast separately and then assembled together.

Recognition

National Institute of Fashion Technology Winner - Best Graduate Design Project Award, 2017

National Institute of Fashion Technology Winner - Most Exemplary Use of Design Methodology Award, 2017

National Institute of Fashion Technology Winner - Best Graduate Design Project Award, 2017

National Institute of Fashion Technology Winner - Most Exemplary Use of Design Methodology Award, 2017

National Institute of Fashion Technology Winner - Best Graduate Design Project Award, 2017

National Institute of Fashion Technology Winner - Most Exemplary Use of Design Methodology Award, 2017